How to install the vortex flowmeter reasonably?

Vortex flowmeter is an indispensable instrument for measuring flowmeters in industrial production. It can measure gases such as superheated steam, nitrogen, etc., and measure liquids such as water and methanol. Let's talk about how to properly install the gas vortex flowmeter![]()

(1) Gas vortex flowmeter installation environment requirements:

1. Avoid strong electrical equipment, high-frequency equipment, and strong switching power supply equipment as much as possible. The power supply of the meter is separated from these devices as much as possible.

2. Avoid the direct effects of high temperature heat sources and radiation sources. If it must be installed, it must be insulated and ventilated.

3. Avoid high humidity environment and strong corrosive gas environment. If it must be installed, ventilation is required.

4. Vortex flow meters should be avoided to be installed on pipes with strong vibration. If it must be installed, a pipe fastening device shall be installed at the upstream and downstream 2D, and an anti-vibration pad shall be added to enhance the anti-vibration effect.

5. The instrument should be installed indoors. It should be waterproof when installed outdoors. Pay special attention to bend the cable into a U shape at the electrical interface to prevent water from entering the amplifier casing along the cable.

6. There should be ample space around the instrument mounting point for wiring and scheduled maintenance.

(2) Gas vortex flowmeter instrumentation pipeline installation requirements:

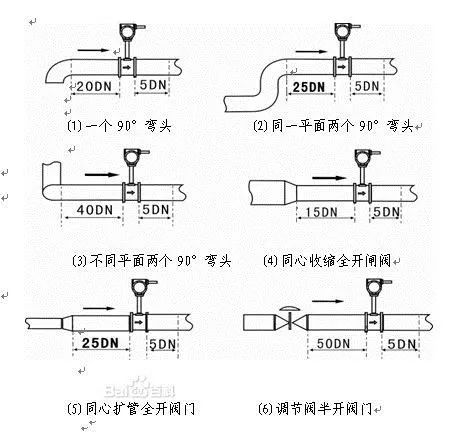

1. The vortex flow meter has certain requirements for the upstream and downstream straight pipe sections of the installation point, otherwise it will affect the flow field of the medium in the pipeline and affect the measurement accuracy of the instrument. The length of the upstream and downstream straight pipe sections of the instrument is shown in the figure below.

Note: The regulating valve should not be installed upstream of the vortex flow meter as much as possible, but should be installed at the downstream 10D of the vortex flow meter.

2. The inner diameters of the upstream and downstream pipes should be the same. If there is a difference, the inner diameter Dp of the piping and the inner diameter Db of the vortex meter body should satisfy the following relationship: 0.98Db≤Dp≤1.05Db, and the downstream piping should be concentric with the inner diameter of the flow meter body. The different axial degrees between them should be Less than 0.05Db

3. The gasket between the meter and the flange cannot protrude into the tube during installation. The inner diameter should be 1-2mm larger than the inner diameter of the body.

4. Installation design of pressure tap and temperature measuring hole. When the temperature and pressure transmitter need to be installed in the pipeline to be tested, the pressure measuring hole should be set at 3-5D downstream, and the temperature measuring hole should be set at 6-8D downstream, as shown in Figure (7). D is the nominal diameter of the meter, unit: mm

5. The meter can be mounted horizontally, vertically or tilted on the pipe.

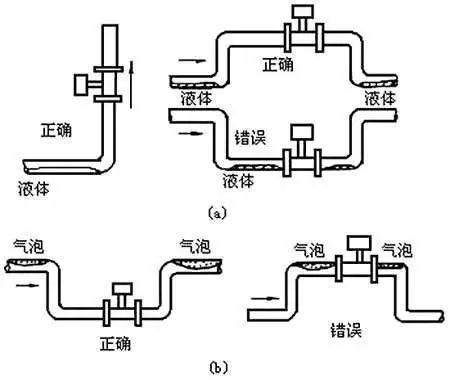

6. When measuring gas, the instrument is installed in a vertical pipe, and the gas flow direction is not limited. However, if the pipeline contains a small amount of liquid, in order to prevent liquid from entering the metering tube, the airflow should flow from bottom to top, as shown in Figure (4)a.

7. When measuring liquids, in order to ensure that the tubes are filled with liquid, the direction of liquid flow should be guaranteed from bottom to top when installing the meter in vertical or inclined pipes. If the pipeline contains a small amount of gas, in order to prevent gas from entering the metering tube, the meter should be installed at the lower part of the pipeline. as the picture shows

8. When measuring high temperature and low temperature media, attention should be paid to insulation measures. The high temperature inside the converter (in the header housing) should not exceed 70 °C; the low temperature tends to cause condensation inside the converter, reducing the insulation resistance of the printed circuit board and affecting the normal operation of the instrument.

Contact: Charlie

Phone: +86 18698620567

Tel: +86 41183897455

Email: Charlie@tereninstruments.com

Add: No75,HuiLi street, HuaNan industrial district,DaLian,China

We chat